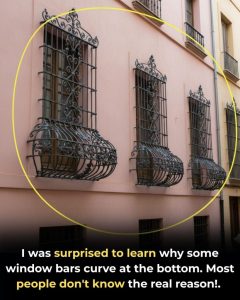

Have you ever noticed that many window bars feature a gentle curve along the bottom?

It’s not a random design choice.

That subtle bend is where smart engineering meets everyday functionality.

Because true security isn’t just about thick metal and strong welds —

it’s about thoughtful design working quietly in the background.

🛠️ Structural Strength: The Engineering Behind the Curve

The most important reason window bars are curved at the bottom is structural reinforcement — not decoration.

This design reflects a timeless architectural principle:

An arch distributes force more efficiently than a flat beam.

While window bars don’t hold up buildings, they still need to withstand pressure — whether from attempted tampering or environmental stress.

How the Curve Makes a Difference:

-

A straight horizontal bar can flex or sag under force, especially if the metal is thinner.

-

A downward curve (forming a shallow “U” or “V” shape) increases rigidity.

-

The bend strengthens the metal through tension, making it more resistant to bending or prying.

Think of it like a potato chip:

Flat, it snaps easily. Add a curve, and suddenly it becomes much harder to break.

✅ The result? A stronger security system — without adding bulk or expensive materials.

🌧️ Better Drainage, Less Rust

Outdoor window guards are constantly exposed to rain and moisture.

A flat horizontal bar can collect water in the center, which may lead to:

-

Rust and corrosion

-

Gradual weakening of the metal

-

Staining on walls or window sills

When the bar curves downward:

-

Water naturally runs off to the sides

-

The metal dries faster

-

Long-term durability improves

This is especially important in rainy climates or coastal areas where salty air accelerates corrosion.

A small curve can dramatically extend the life of the installation.