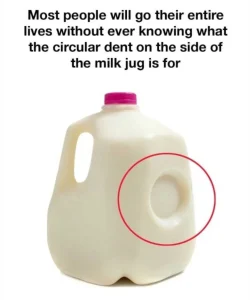

At first glance, the small circular dent found on the side of a plastic milk jug might appear trivial—or even mistakenly thought of as a manufacturing defect. However, this subtle design feature is far from accidental. It plays several important roles that improve the jug’s overall performance, durability, and environmental impact. This simple yet smart engineering detail highlights how careful design can make everyday products not only more functional but also more sustainable.

Managing Pressure Inside the Jug

When a milk jug is filled, the liquid inside exerts constant pressure on the jug’s walls. This pressure isn’t static; it can change depending on a variety of factors such as temperature fluctuations, altitude changes, and movement during transport. For example, warmer temperatures cause the milk and the air inside to expand, increasing internal pressure. Without a way to accommodate this change, the jug might warp, bulge, or even crack.

The circular indentation serves as a flexible “pressure valve” of sorts. It allows the plastic surface to flex slightly inward or outward, absorbing these changes in pressure without compromising the jug’s structural integrity. This flexibility helps prevent damage like ruptures or permanent deformation, ensuring that the container maintains its shape and keeps the milk safely enclosed.

Preventing Breakage During Transport and Handling

Milk jugs endure a lot of wear and tear on their journey from production lines to your refrigerator. They are often subjected to rough handling, being stacked on pallets, jostled during transit, or exposed to temperature variations in trucks or stores. All these factors place stress on the jug, increasing the risk of cracks or breaks.

Here, the circular dent acts as a shock absorber. By providing a deliberate weak spot, the indentation helps the jug absorb impacts more effectively, reducing stress concentrations that might otherwise cause the plastic to fracture. Additionally, if the jug is accidentally dropped or bumped, the dent offers a small amount of “give,” cushioning the blow and minimizing the chance of catastrophic spills or leaks. This design thus contributes to the jug’s overall durability, protecting both the product inside and the environment from waste.

Reducing Plastic Use for Greater Sustainability

In today’s environmentally conscious world, reducing plastic consumption is a major priority. The circular dent is not just about strength and flexibility — it also serves an eco-friendly purpose. By incorporating this indentation, manufacturers can maintain the jug’s structural integrity while using less plastic overall.

Without this feature, the jug would require thicker, heavier walls to resist pressure changes and impacts, meaning more raw material consumption and a bigger carbon footprint. The dent strategically redistributes stress, allowing the jug to be made lighter and thinner without sacrificing durability. This means fewer resources used during production and less plastic waste over time, contributing positively to sustainability efforts.